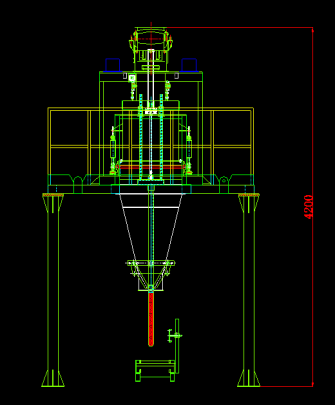

SW-JP-F-25 pumping type vibration feeding packaging machine

Summary: SW-JP-F-25 is a special packaging machine for powder materials with high gas content developed by Zaozhuang Sunweigh Technology Co., Ltd. It adopts vibration feeding mode to overcome the material residue in the feeding tube caused by screw feeding mode, and is suitable for small batch powder material packaging with frequent material replacement. SW-JP-F packaging machine is equipped with vacuum pumping system, which can extract excess air from ultra-fine powder to meet the automatic packaging of ultra-fine powder materials. It can be equipped with automatic folding and automatic packaging system according to needs, saving labor, improving management level and reducing management costs. The bag needs to be artificially wrapped at the outlet. It is mainly suitable for powder automatic quantitative packaging equipment in flour, starch, feed, food, chemical, light industry, medicine and other industries. The equipment effectively solves the problems of inaccurate weighing, slow packing speed, sticking and punching caused by the great change of dry and humidity of materials. It is mainly equipped with weighing mechanism, pumping mechanism, feeding mechanism, body frame, control system, conveyor and sewing machine, etc. It needs manual assistance in bagging.

Working principle

Before packaging, the air-pumping vibration feeding packaging machine needs to set the weight on the instrument. Manually, the bag is put into the lower outlet, and the clamping switch is switched on. After receiving the signal, the control system is clamped by the bag-clamping device. At the same time, the air-pumping mechanism starts the air-pumping mechanism and the feeding mechanism. At the same time, the air-pumping mechanism inserts the air-pumping pipe into the bag, and the material is sent to the packing bag by the bin. The structure is vibration feeding. When the material in the packing bag reaches the set weight, the silo stops discharging, and the air pipe is withdrawn. The belt holder automatically loosens the packing bag, and the packing bag falls on the conveyor belt. The conveyor belt conveys the packing bag to the sewing machine for manual auxiliary packing. This completes a packaging process.

Main technical parameters

1. Feeding mode: Vibration feeding

2. Packing speed: 200-300 packages/hour

3. Packaging accuracy: 0.2%

4. Packaging range: 25kg

5. Gas consumption: 10 cubic meters/h, air pressure 0.4-0.6mp

6. Equipment power: 3.7 kw

7. Power supply: AC380V, 50HZ

8. Pumping Mode: Vacuum Tube Insertion and Pumping

9. Dust removal: spare dust removal outlet, directly connected to the dust removal system.

Functional characteristics

1. The machine needs manual bagging, automatic weighing, bagging, filling, automatic conveying and packing.

2. Vibration feeding mode is adopted to ensure that there is no material residue in the silo, and the cutting speed and accuracy are guaranteed by instrument control.

3. Adopt special sealing method to meet environmental protection requirements

4. Using frequency conversion to control feeding speed to ensure packaging accuracy

5. 304 stainless steel is used in the contact part with materials, chemical raw materials are used, and the anticorrosion performance is good.

6. High-end electrical components, long service life, good stability

7. Using stainless steel bellows sensor, it has high stability of anti-corrosion and transmission signal.

8. The control cabinet is made of dust-proof seal, which is suitable for harsh dust environment.

9. Automatic correction of material overshoot, automatic tracking of zero point, automatic detection and control of overshoot, alarm of overshoot and undershoot

10. Auto-folding and auto-encapsulation system can be selected to save labor.

Configuration sheet

Serial number, name, manufacturer and model number

1. Stainless steel structure weighing platform set of Zaozhuang Sunweigh

2. Stainless steel bellows transducers

3. Digital Weighing Instrument GM-8804C

4. Control cabinet Zaozhuang Sunweigh

5. Vibration feeding device Zaozhuang Sunweigh 2.2 kw

6. Matching Cylinders: Taiwan Yadek SC32*50 2

7. Solenoid Valves 4 in Festo, Germany

8. Sewing Bag Conveyor Zaozhuang Sunweigh B450*3000 1 Set 0.75 kw

9 Sewing Machine, Hebei Qing Sewing Machine

10. Flanging Machine, Zaozhuang Sunweigh Machine 1 set

11. Powerful Fan and Drainage System Zaozhuang Sunweigh 1 set 0.55 kw

Shopping guide

SW-JP-F-25 air-pumped vibration feeding packaging machine is a quantitative packaging machine and semi-automatic powder packaging machine. It is the preferred equipment for enterprises with low production requirements. Because the vibration feeding packaging machine of exhaust test effectively solves the problem of residual materials in the tube of screw packaging machine. Make enterprises no longer need to be headached by the inaccuracy of weighing.

Video case

【Related Product】

- Bulk Full-automatic Loading Machine

- Pallet Full-automatic Loading Machine

- Ton Bag Full-automatic Loading Machine

- Small Bag Full-automatic Loading Machine

- Fully Automatic Bulk Bag Packaging Machine

- SW-JP-F-25 pumping type vibration feeding packaging machine

- Full - automatic packaging machine for organic fertilizer

- Valve Packing Machine/Scale

【Relevant Articles】

- Application Characteristics of Potassium Dihydrogen Phosphate Full-auto

- How to Select the Type of Full-automatic Ton Bag Packing Machine for Co

- Selection of Automatic Packing Machine for White Granulated Sugar Produ

- Detection and anticorrosion of electrical components of automatic packi

- Requirements of Full-automatic Ton-bag Packing Machine for Ton Bags

- The selection and application of potassium tert-butyl alcohol in automa

- Zaozhuang Sunweigh teaching you how to choose packaging machine

- Leadership of the municipal government to visit Zaozhuang Sunweigh Tech

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018