Present Situation of Automatic Batching System in Friction Industry

Friction material plays an important role in automobile braking system. The different ratios of various materials directly affect the safety of driving and the braking effect. In traditional technology, manual weighing is the main method. The development of the industry is restricted by pollution, low efficiency and poor accuracy. Friction materials are usually produced by a dozen or even dozens of raw materials proportionally. Because of the difference of materials, automatic batching is difficult to achieve. Therefore, many manufacturers adopt manual batching. This will inevitably lead to mismatching or mismatching, moreover, this method has many shortcomings, such as large error, poor labor environment and so on.

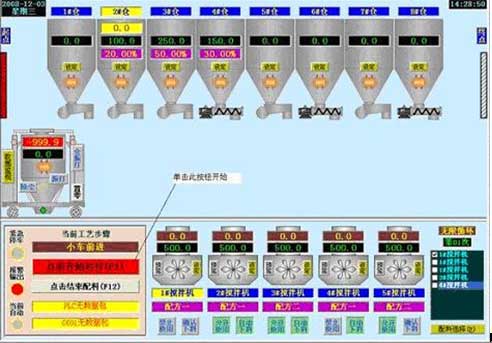

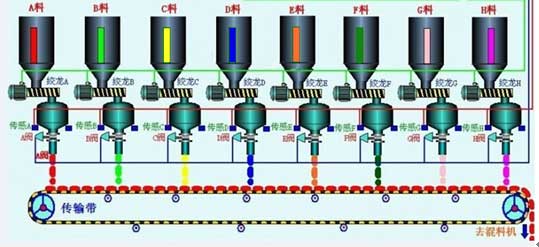

The batching system of friction materials used by brake pad manufacturers in friction industry can be roughly divided into two types according to the conveying mode, one is trolley conveying mode, the other is belt conveying mode. And they can't meet the needs of all customers. The following drawings are the detailed drawings of the ingredient system used by some customers.

1. Transport mode of trolley in friction material proportioning system

The conveying mode of trolley in friction material batching system is inadequate:

1. The feeding mode of automatic batching system is single, and materials with poor fluidity can not be fed automatically.

2. No weighing bucket, weighing only by car, slow speed

3. There is no duplicate weighing device in automatic batching system, which can not guarantee accuracy.

2. Belt conveying mode of friction material proportioning system

The belt feeding mode of friction material batching system is inadequate.

1. The feeding mode of automatic batching system is single, and materials with poor fluidity can not be fed automatically.

2. Without taking measures to solve the problem of belt adhesives, the accuracy can not be guaranteed.

3. There is no duplicate weighing device in automatic batching system, which can not guarantee accuracy.

3. The shortcomings of friction material batching system are summarized as follows:

1. The proportioning accuracy of friction material proportioning system is 0.5%-1%.

2. The speed of automatic batching system is 7-15 minutes.

3. The materials with poor fluidity, such as steel fibers and glass fibers, can not be fed automatically and need manual auxiliary feeding. As a result, the automatic batching system becomes a semi-automatic batching system.

4. Defects in Friction Material Batching System Design

(1) The discharge of the weighing hopper is not clean.

(2) The powder material spills out of the belt during discharging.

(3) There are some problems in the selection of feeding methods, all of which are spiral feeding. The whole friction material proportioning system should consist of a spiral feeding, B vibration feeding, C belt feeding and D gravity feeding.

5. The conveying mode of friction material proportioning system is single. It is conveyed only by belt or by car. It can not be flexibly changed according to the customer's situation.

6. The dust removal effect of friction material proportioning system is poor.

- Last:请返回Next

- Next:Will the starch industry be profitable in 2016?

【Related Product】

- Full-automatic Packaging Machin

- Semi-automatic valve bag packin

- Semi automatic powder packaging

- SW-ATF-180 Fully Automatic Pack

- Semi-automatic Ton bag Packing

- Double hopper granule packing m

- Single hopper packing machine

- Semi-automatic packing machine

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018