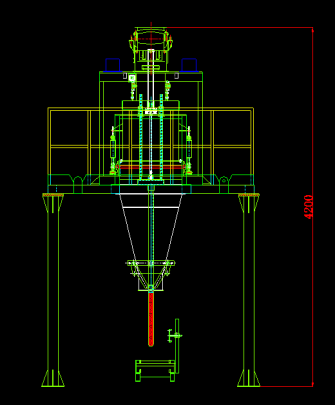

Intermediate Weighing Machine

Intermediate weighing machine SW-NCS is also called flow scale, bulk material scale, bulk grain scale, bulk weight, cumulative weight, etc. In the transportation of bulk materials, it is often required to measure the weight of the materials without interrupting the material flow. This weight value can be used to settle the inventory, master the cost of raw materials consumption, and ideally control the production process within the enterprise. The surface of the intermediate weighing machine is a kind of dynamic scale, and the essence is to carry out cumulative measurement through static measurement. The function of the intermediate weighing machine SW-NCS is similar to that of a belt scale, but it overcomes the defects of poor accuracy, large volume and horizontal feeding of the belt scale, and has been widely used in enterprise production processes. The intermediate weighing machine SW-NCS overcomes the shortcomings of belt weigher, the accuracy can reach 0.2%, and it can be installed in the appropriate position of enterprise production process line according to local conditions. The characteristics of the intermediate weighing machine are dynamic flow and static weighing. Material enters from the entrance of bulk grain scale and flows out smoothly from the exit. The material always moves continuously, but the measuring bucket of the intermediate measuring scale is a static and stable measuring bucket by bucket.

Product features of intermediate weighing machine SW-NCS:

The intermediate weighing machine SW-NCS can meet different installation occasions and meet trade settlement requirements.

The intermediate weighing machine SW-NCS has a high speed A/D conversion rate of 300 times per second and Tra×DSPTM anti-vibration technology.

Intermediate weighing machine SW-NCS is equipped with specialized weighing mechanism, which is simple, fast, stable and reliable to operate.

Industrial weighing control terminal and high precision weighing sensor are adopted.

Strict surface treatment technology, suitable for a variety of environments.

The middle weighing machine adopts a special material wear-resistant layer to prolong the service life of the equipment.

Equipped with automatic weighing device, it simplifies the daily correction work.

Setting pressure balance system improves weighing accuracy.

The intermediate weighing machine SW-NCS is equipped with various computer interfaces ( RS232/422/485 ).

Due to the advantages of the intermediate weighing machine SW-NCS, it is widely used, for example:

1. Wheat out-of-warehouse measurement in flour mills: When a flour mill produces 100 tons of flour, it must know how much wheat it consumes. If there is no intermediate weighing machine to provide accurate weight data, does it consume 120 tons of wheat or 150 tons of wheat to produce 100 tons of flour? Therefore, basically all flour mills need to install an intermediate weighing machine between the steel plate warehouse and the production line to accurately record the amount of wheat entering the processing line so as to calculate the consumption and flour yield.

2. Measurement of raw material corn in and out of the warehouse of starch factory: The purchased raw material corn enters the raw material steel plate warehouse through sorting, and the weighing machine in the middle of the warehouse accurately measures the actual weight entering the steel plate warehouse; The actual weight of corn needs to be measured by an intermediate weighing machine before entering the processing line, so as to measure the corn consumption per unit starch.

3. The intermediate weighing machine for ports is a measuring instrument integrating weighing, transportation, storage and settlement. For a long time, the weighing and storage of bulk materials in ports or railway grain, chemical and other industries are labor-intensive operations, which not only have high labor intensity, slow speed, but also have poor measurement accuracy. The use of intermediate weighing machines effectively solves all the problems, and really carries out continuous, fast and accurate weighing on bulk materials, thus reducing process links, reducing labor intensity and greatly improving labor productivity.

4. Discharging measurement of imported bulk materials: The unloading of imported bulk materials ( such as corn and soybean ) needs to be measured by an intermediate weighing machine for payment settlement and weight check. Intermediate weighing machines are widely used and installed in various forms. It can be used not only for trade settlement measurement, but also for enterprise internal management measurement. The metering speed can reach 1000 tons / hour.

According to different manufacturers, anti-vibration technology can be added to the intermediate weighing machine to improve the accuracy and an automatic checking mechanism can be added.

With the improvement of instrument performance, the current bulk scale has a variety of computer interfaces, convenient and flexible access to the enterprise's internal management system.

Technical parameters of intermediate weighing machine SW-NCS:

| Serial | Model | Weighing Capacity | Weight of Equipment | Height | length | Width |

| 1 | NCS-10 | 10t/h | 350kg | 2500 | 700 | 900 |

| 2 | NCS-50 | 50t/h | 510kg | 2800 | 850 | 1000 |

| 3 | NCS-80 | 80t/h | 535kg | 3000 | 850 | 1200 |

| 4 | NCS-100 | 100t/h | 800kg | 3950 | 1000 | 1500 |

| 5 | NCS-150 | 150t/h | 850kg | 3950 | 1000 | 2000 |

| 6 | NCS-200 | 200t/h | 1200kg | 4000 | 1100 | 2000 |

| 7 | NCS-300 | 300t/h | 1500kg | 5600 | 1200 | 2000 |

【Related Product】

- Bulk Full-automatic Loading Machine

- Pallet Full-automatic Loading Machine

- Ton Bag Full-automatic Loading Machine

- Small Bag Full-automatic Loading Machine

- Fully Automatic Bulk Bag Packaging Machine

- SW-JP-F-25 pumping type vibration feeding packaging machine

- Full - automatic packaging machine for organic fertilizer

- Valve Packing Machine/Scale

【Relevant Articles】

- Application Characteristics of Potassium Dihydrogen Phosphate Full-auto

- How to Select the Type of Full-automatic Ton Bag Packing Machine for Co

- Selection of Automatic Packing Machine for White Granulated Sugar Produ

- Detection and anticorrosion of electrical components of automatic packi

- Requirements of Full-automatic Ton-bag Packing Machine for Ton Bags

- The selection and application of potassium tert-butyl alcohol in automa

- Zaozhuang Sunweigh teaching you how to choose packaging machine

- Leadership of the municipal government to visit Zaozhuang Sunweigh Tech

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018