HT series pneumatic conveying system

Zaozhuang Sunweigh Technology Co., Ltd. is a high-tech enterprise specializing in the design, development, sales, installation, commissioning and after-sales service of automatic batching, solid material pneumatic conveying and injection system, automatic packaging, palletizing and other equipment.

The company's main products: pneumatic conveying system, automatic packaging scale, high-level palletizer, automatic bagging machine, automatic bagging machine, ton bag packaging scale, granular packaging scale, powder packaging scale, flow scale, liquid filling scale, automatic proportioning equipment system, bag breaker, bagging station, automatic valve mouth scale, etc.

Pneumatic conveying is a comprehensive technology, which involves fluid mechanics, material science, automation technology, manufacturing technology and other fields. It is a high-tech project with high conveying efficiency, less land occupation, economy and pollution-free.

Pneumatic conveying system can be divided into dilute phase, dense phase and semi-dense phase. According to the type of powder: positive pressure, negative pressure, positive and negative pressure combination system. Advantages: high efficiency, less land occupation, economy and pollution-free.

Pneumatic conveying system features: fully enclosed pipeline conveying system, flexible layout, no secondary pollution, high efficiency and energy saving, easy material conveying and recycling, no leakage conveying. Pneumatic conveying system is controlled by computer with high degree of automation. It will replace traditional mechanical conveying with powerful advantages.

The application of pneumatic conveying system: With the rapid development of economy and the continuous expansion of production in all walks of life, more and more attention has been paid to the environmental pollution caused by some raw materials and powder materials in some industries, such as thermal power plants, chemical plants, cement plants, pharmaceutical plants and grain processing plants. So the pneumatic conveying technology has been gradually promoted. Pneumatic conveying is an important link in clean production. It is a process of replacing traditional mechanical conveying material with closed conveying pipeline, and it is a modern logistics system suitable for bulk material conveying.

Introduction of HT Series Pneumatic Conveying System

HT series pneumatic conveying system is an ideal equipment for conveying powder and granular materials. It is suitable for conveying powder and granular materials such as plum ash, quicklime, cement, various kinds of materials, carbon powder, grain, translucent stone powder, aluminium fluoride, aluminium hydroxide, chemical raw materials, etc.

HT pneumatic conveying system absorbs advanced technology of similar products in China. After many innovations in its long-term use, HT pneumatic conveying system has stable quality, reliable performance, wide range of use and high efficiency. It is an ideal equipment for pneumatic conveying. For the transportation of high specific gravity and large particulate matter, it also shows its unique excellent performance, and the products are sold all over the country.

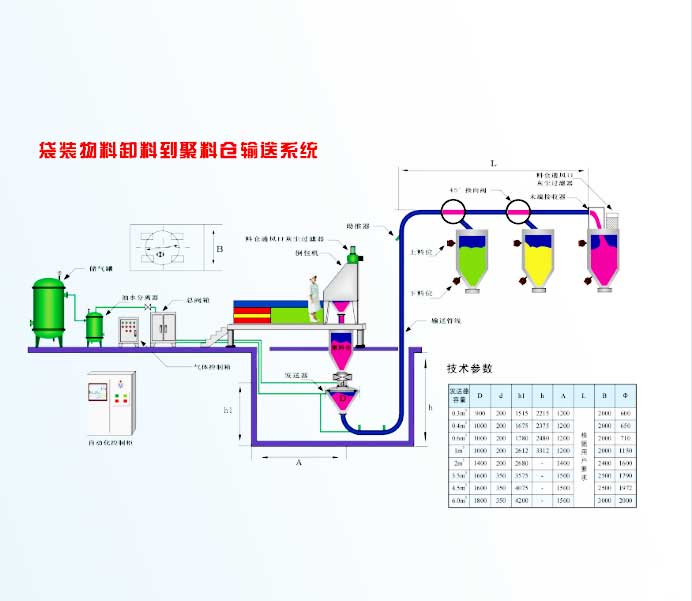

1. Bag material unloading to the conveying system of the aggregate bin:

Mainly includes: multiple transmitters parallel dust removal system, double transmitters continuous conveying system, weighing and conveying system, mixing bin and regional conveying system, etc.

2. Pulse bag filter:

HT series pneumatic conveying system pulse bag filter generally consists of three parts:

The upper box body consists of cover plate and exhaust port, the lower box body consists of frame and filter bag assembly, and the ash cleaning system consists of electromagnetic pulse valve and pulse signal controller.

Technical parameters of pulse bag filter for HT series pneumatic conveying system:

| DMC -12 | DMC -24 | DMC -36 | DMC -48 | DMC -60 | DMC -72 | DMC -84 | DMC -96 | DMC -108 | DMC -120 | ||

| Filter Area | 9 | 18 | 27 | 36 | 45 | 54 | 63 | 72 | 84 | 90 | |

| Pcs | 12 | 24 | 36 | 48 | 66 | 72 | 84 | 96 | 108 | 120 | |

| Bag specifications | φ120*2000 | ||||||||||

| Operating temperature(℃) | ≤120 | ||||||||||

| (Mpa) | 1000-1500 | ||||||||||

| Dusting efficiency | 99% | ||||||||||

| Dust concentration entrance | 15(g/㎥) | ||||||||||

| Filtering wind speed m/min | 0.5-0.2 | ||||||||||

| Treatment air volume㎥/h | 270-1080 | 540-2160 | 810-3240 | 108-4320 | 1350-5400 | 1620-6450 | 1890-8560 | 2160-8640 | 2430-9780 | 2700-10800 | |

| Paint pressure(Mpa) | 0.5-0.7 | ||||||||||

| ASCO(个) | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | |

| Pulse width(m) | 0.1-0.2 | ||||||||||

| Pulse interval(s) | 60-120 | ||||||||||

| Pulse spacing(s) | 1-50 | ||||||||||

3. HT dust collector:

HT type dust collector of HT series pneumatic conveying system is carried out through cloth bags. It is used for air purification after discharger in pneumatic conveying equipment. It can also be used in flour industry and refractory processing workshop. The dust filtering efficiency can be more than 98%. Its structure is equipped with several cloth bags in the shell. When the dusty air passes through, the solid phase can be effectively separated from the gas phase, so that the micro-materials in the air flow can be adsorbed on the filter bags or settled down. In order to remove the dust of the cloth bags, the vibration motor of the air valve is activated to make the cloth bags regenerate.

Technical parameters of HT type dust collector for HT series pneumatic conveying system:

| Type | Pcs | Filtering area(㎡) | Blowing rate(㎥/h) | Pa(kg/㎡) |

| TT-12 | 12 | 14 | 2100 | 80-100 |

| HT-24 | 24 | 28 | 4300 | 80-100 |

| HT-32 | 36 | 38 | 5800 | 80-100 |

| HT-48 | 48 | 58 | 8600 | 80-100 |

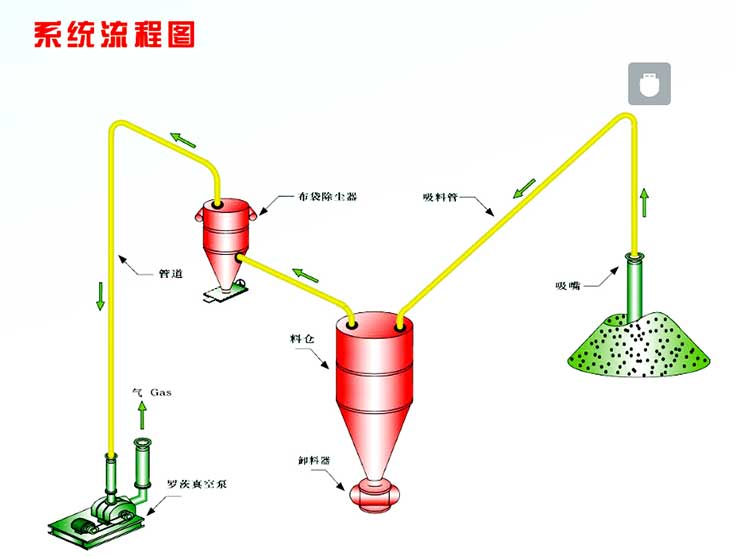

The working principle of HT series pneumatic conveying system:

HT series pneumatic conveying system uses vacuum pump installed at the end of the conveying system to suck the air in the system. A negative pressure airflow below atmospheric pressure is formed in the conveying pipe. Material enters the pipeline together with the atmosphere from the starting suction nozzle. As the airflow is conveyed to the end separator, the material particles are separated from the airflow by gravity or centrifugal force, and the gas is dedusted by a centrifugal fan. Or vacuum pump into the atmosphere.

HT series pneumatic conveying system features:

HT series pneumatic conveying system is a pneumatic conveying system which takes Roots vacuum pump as air source and continuously sucks materials. HT series pneumatic conveying system can convey materials from several places to one place centrally. The conveying pressure is low, the conveying is reliable and the equipment is simple. Because the pressure in the system is lower than atmospheric pressure, the conveyed materials will not overflow from the system; because the suction nozzle sucks materials, it can be avoided. The dust of material points is flying, and the production efficiency is high.

Compared with similar products and mechanical conveying, HT series pneumatic conveying system has unique advantages:

1. HT series pneumatic conveying system has compact equipment, small area and low maintenance cost.

2. HT series pneumatic conveying system adopts PLC operating system, which can be controlled by PLC programmable controller or relay according to user's requirements. It implements manual and automatic control with simple and flexible operation and high degree of automation.

3. The fluidization device has more unique features and flexible control means. It can fully fluidize the conveying materials, improve the conveying efficiency, ensure the conveying quality, and have no residual materials.

4. HT series pneumatic conveying system conveyor pipes can be flexibly arranged, suitable for ultra-high, long distance, to achieve efficient conveying.

5. Multi-sending device and use can realize continuous whole line, eliminating the usual time loss in the feeding process, and maximizing the utilization rate and efficiency of the pipeline.

6. Because it can be transported in sealed pipeline, the quality of materials can be strictly guaranteed not to be affected by moisture, pollution and various climatic conditions. It is conducive to production and environmental protection, and it is the most ideal environmental protection and energy saving equipment.

Main technical parameters and shape dimensions of HT series pneumatic conveying system

Technical parameters of HT series pneumatic conveying system

HT series pneumatic conveying system components

HT series pneumatic conveying system system components include: stainless steel unloading hopper, three-way reversing valve, air chute, lining ceramic wear-resistant elbow, accelerating pipe, arch breaking current aid, booster, in-situ box, PLC computer automatic control, etc.

【Related Product】

- Full-automatic Packaging Machine

- Semi-automatic valve bag packing machine

- Semi automatic powder packaging machine

- SW-ATF-180 Fully Automatic Packaging Machine for Ton Bag

- Semi-automatic Ton bag Packing machine

- Double hopper granule packing machine

- Single hopper packing machine

- Semi-automatic packing machine without hopper

【Relevant Articles】

- Application Characteristics of Potassium Dihydrogen Phosphate Full-auto

- How to Select the Type of Full-automatic Ton Bag Packing Machine for Co

- Selection of Automatic Packing Machine for White Granulated Sugar Produ

- Detection and anticorrosion of electrical components of automatic packi

- Requirements of Full-automatic Ton-bag Packing Machine for Ton Bags

- The selection and application of potassium tert-butyl alcohol in automa

- Zaozhuang Sunweigh teaching you how to choose packaging machine

- Leadership of the municipal government to visit Zaozhuang Sunweigh Tech

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018