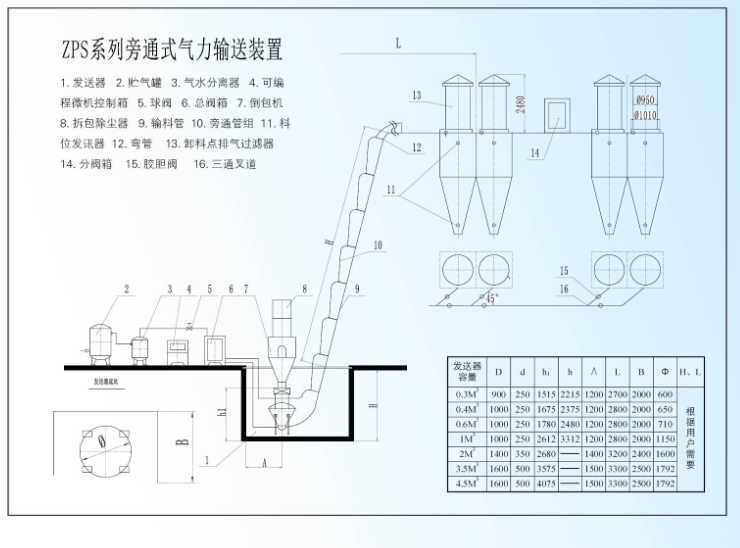

ZSP Series Bypass Pneumatic Conveying System

ZSP series bypass pneumatic conveying system has a wide range of applications and is suitable for conveying powdery materials in casting, cement, grain, medicine, chemical industry, metallurgy and other industries. In particular, it absorbs the technology of PNEUMOSPLOT device of WESCHLE Company of Germany to make the application range of ZSP series bypass pneumatic conveying system wider. ZSP series bypass pneumatic conveying system is suitable for conveying fuel, graphite, polyester chips, ore sand and various powder and granular materials without blocking phenomenon.

ZSP series by-pass pneumatic conveying system adopts the principle of low pressure by - pass, programmable microcomputer automatic control, new structure, advanced technology, and has the advantages of less gas consumption, high conveying efficiency, stable and reliable operation, flexible and convenient arrangement, good dust removal effect, multi-point discharge, improved working conditions, etc. ZSP series by-pass pneumatic conveying system can be restarted after the conveying is interrupted due to emergency shutdown, so that the pipeline blockage phenomenon does not occur, and the system is suitable for conveying materials with high fluidity and adhesion. As the conveying is stable and appropriate, the pipeline abrasion and the self pulverization of the materials are also reduced.

Main Equipment of ZSP Series Bypass Pneumatic Conveying System

ZSP series bypass pneumatic conveying system consists of transmitter, air storage tank, air-water separator, programmable microcomputer control box, ball valve, main valve box, rewinding machine, unpacking dust remover, conveying pipe, bypass pipe set, material level transmitter, elbow pipe, discharge point exhaust filter, branch valve box, rubber bladder valve, three-way fork, etc.

Main technical parameters of ZSP series bypass pneumatic conveying system:

| Serial | Item | Parameter | |

| 1 | Transmit type | Bypass type | |

| 2 | Transmitter effective area(m3) | 0.3,0.4,1.0,2.0,3.5,4.5 | |

| 3 | Conveying distance | Horizontal distance(m) | 15-100 |

| Vertical distance(m) | <60 | ||

| 4 | Conveying pipe diameter and conveying capacity | Φ108*4.5 mm(Ton per Hour) | 25-35 |

| Φ133*5mm(Ton per Hour) | 35-50 | ||

| Φ≥159mm(Ton per Hour) | 50-200 | ||

| 5 | Weight mixing concentration ratio of feeder | 12-20 | |

| 6 |

Air consumption |

<50 m(m3./ton of material) | 15-20 |

| 50-100 m(m3./ton of material) | 25-35 | ||

| 100-200m m3./ton of material | 30-40 | ||

| 200-500m m3./ton of material | 40-60 | ||

| 7 | Air source pressure(Mpa) | 0.59 | |

| 8 | Capacity of air storage tank(m3) | 2-10 | |

| 9 | Power Index(Watt/Ton /Hour*meter) | 0.015-0.03 | |

| 10 | Number of discharge points(Can be customized according to users) | ||

| 11 | total weight (KG) | 4-15 | |

【Related Product】

- Full-automatic Packaging Machine

- Semi-automatic valve bag packing machine

- Semi automatic powder packaging machine

- SW-ATF-180 Fully Automatic Packaging Machine for Ton Bag

- Semi-automatic Ton bag Packing machine

- Double hopper granule packing machine

- Single hopper packing machine

- Semi-automatic packing machine without hopper

【Relevant Articles】

- Application Characteristics of Potassium Dihydrogen Phosphate Full-auto

- How to Select the Type of Full-automatic Ton Bag Packing Machine for Co

- Selection of Automatic Packing Machine for White Granulated Sugar Produ

- Detection and anticorrosion of electrical components of automatic packi

- Requirements of Full-automatic Ton-bag Packing Machine for Ton Bags

- The selection and application of potassium tert-butyl alcohol in automa

- Zaozhuang Sunweigh teaching you how to choose packaging machine

- Leadership of the municipal government to visit Zaozhuang Sunweigh Tech

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018