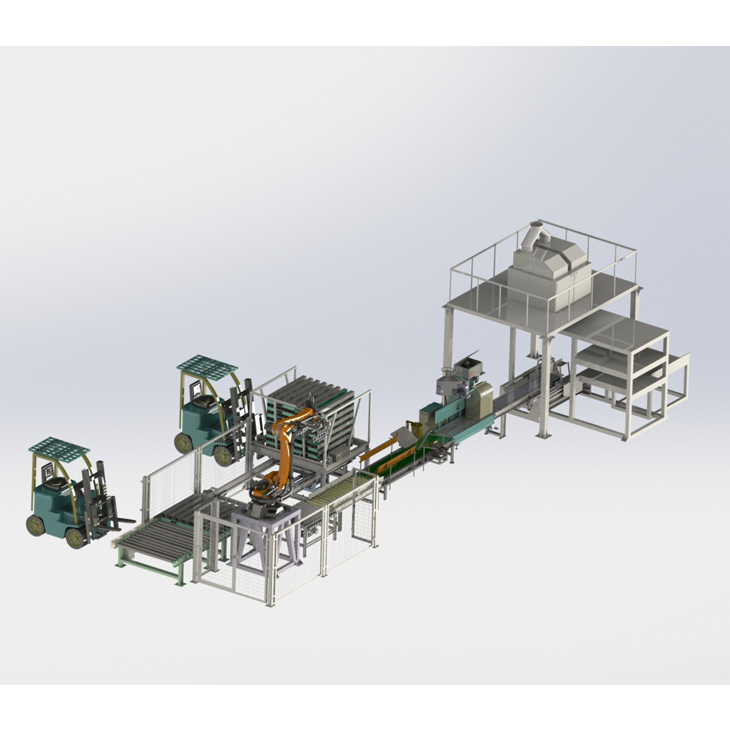

Fully automatic packaging machine

一、Composition of fully automatic packaging machine equipment:

Fully automatic packaging machine is composed of automatic bag feeding mechanism, bag feeding mechanism, automatic weighing and weighing packaging scale, bag clamping device, folding hot seaming machine, bag pouring machine, plastic machine, metal detection machine, conveyor rejector, weight re-inspection machine, conveyor rejector, inkjet printer, other selection equipment, electrical instrument control cabinet and various conveyors.

1. Automatic weighing quantitative packaging scale:

The automatic weighing and quantitative packaging scale of the automatic packaging machine uses HBM series sensors imported from Germany and German Gemmann instruments imported from Canada. The material of the contact part is stainless steel, and the contact part polishes more than 200 meshes.

2. Bag feeding mechanism:

The bag feeding mechanism of automatic packaging machine adopts two-position automatic switching mode and is driven by motor to realize the functions of bag feeding and bag shifting. Two horizontally arranged trays can store 200 empty bags (depending on the thickness of the package). When one stack of bags is exhausted, another stack of bags will automatically arrive at the position of picking up bags to ensure that there is no pause in loading bags. When you need to add pockets, an alarm will be given. When all the pockets are used up, the packaging opportunity will stop working automatically. Bag feeding capacity: 800 bags/h.

3. Bagging mechanism:

Fully automatic packaging machine bagging mechanism double arm bagging manipulator, bionic structure, original design, patented technology, all kinds of pockets can be applied. The action steps of the automatic bagging machine need only five short-range movement steps to complete the bagging once. Therefore, the structure is simple, the operation is convenient, and the overhaul and maintenance workload is greatly reduced. The action of the manipulator is accomplished by servo motor and cylinder, and the action is in place. The angle of the servo motor can be adjusted arbitrarily so as to achieve better connection and cooperation with the automatic bag clamping device. Vacuum pumps used for bagging and opening are made by Bosch, Germany. Main features: 1. Vacuum suction bag, mechanical glove bag;

(2) Bag depot alarm for lack of bags;

(3) alarm of insufficient pressure of compressed air;

(4) Bagging detection and blowing function;

_The material in contact with the material is stainless steel.

4. Bag clamping device:

When the packing bag after filling material is laid down at the lower opening, the bag holder cart is used to hold the bag in the middle of the powder material bag. The bag mouth is clamped and sent to the movable leading device. The movable leading device is connected with the hot-melt seam package system. By entering the sealing transmission chain, the bag mouth is guaranteed to be a zigzag shape, so that the bag can be controlled in the whole process. Adding a vacuum suction port near the importer to absorb the dust from the bag mouth when it is clamped.

5. Hot seaming machine with folding edge:

Function of folding hot-seam baling machine of automatic packaging machine: This device is composed of automatic importing sewing machine, wire breaking alarm, hot-melt electric control system, etc. The bags filled with materials are imported by the automatic import system through the conveyor, and the seams are sewn automatically, and the thread is cut automatically. Then the hot melt bag mouth. In case of thread breaking, the control system of sewing machine will automatically alarm and send out interlocking stop signal, with on-site position detection and operation buttons.

Technical parameters of folding hot seaming machine:

Sealing method: heat sealing

Capability: 800 bags per hour

Sewing machine speed: 2700 rpm

Needle spacing: 7-10.5 mm, adjustable (generally 10 mm)

Speed Regulation: Stepless Frequency Conversion Speed Regulation

Sewing thread: 20*6 vinylon thread: 30/4*3 cotton thread, or the same specification.

Tangent,: automatic

Sewing Machine Lubrication System: Oil Bath Lubrication System

Start and stop of sewing machine: photoelectric switch

Total power: 5.0KW

6. Metal detector:

The metal detection machine of automatic packaging machine adopts GLS/650/300/metal detection probe originally imported from S+S Company of Germany and equipped with self-made belt conveyor. When the packaging bag passes through this unit, such as ferrite or non-ferrite in the bag, the alarm light is on and buzzer is ringing, the signal is sent to downstream eliminator to remove the unqualified bags from the packaging production line, and the user can also choose interlocking work. Can: When encountering metal objects, upstream equipment stops.

7. Automatic culler:

The automatic eliminating machine of the full-automatic packaging machine is composed of the cylinder action eliminating device of the roller conveyor, the sliding bag non-power roller conveyor and the unit equipment control box. The guaranteed speed is 1000 packs/hour.

8. Inkjet printers:

The inkjet printer of automatic packaging machine is SQUID imported SQ-2 inkjet printer. This machine is easy to operate, easy to maintain, low cost and clear inkjet effect. The sprinkler cover is fully sealed with ABS engineering plastic shell. Spray-type content operation panel settings: year, month, day, batch number, time, etc. (Note: Settings can be selected in Chinese to support the model, the buyer needs to specify when ordering).

9. Belt conveyor (depending on the actual situation on site):

The sealed packing bags are smoothly transported through various devices at a constant speed, and the speed can be adjusted through the frequency converter to match the speed of the sewing machine.

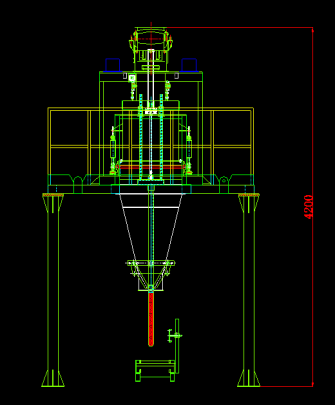

10. Dust removal system:

The dust removal system of fully automatic packaging machine adopts high-pressure spraying to clean the dust in the dust-containing air. It can achieve centrifugal deposition through rounded shell, so that the dust-containing air can obtain high purity (i.e. purification) through filtering medium to meet the requirements of modern environmental protection. The equipment designs several suction points to suck dust from material bin, packaging scale and lower entrance. It can make the packing site free of dust and meet the requirements of environmental protection.

二、The scope of application of fully automatic packaging machines:

Fully automatic packaging machine is suitable for automatic packaging of various packaging bags, such as paper bags, plastic bags, woven bags, etc. Its products are widely used in the automation of the whole process of bagging, weighing, packaging, exporting and eliminating granular, powder, bulk and liquid products in petrochemical, chemical fertilizer, grain, feed, building materials, metallurgy, port, logistics and other industries.

三、Technical characteristics of automatic packaging machine:

1. Fully automatic packaging machine can realize automatic packing bag finishing, automatic opening and absorbing, automatic moving bagging, automatic weighing, counting, filling, moving output, importing automatic folding seam bag of fully automatic seam machine. The whole process of packaging is fully automated, digitized and unmanned, environmentally friendly and low energy consumption.

2. Fully automatic packaging machine is controlled by touch screen. It is convenient to operate, switch specifications and maintain. It is safe and reliable. The whole set of equipment has complete automatic detection procedures, automatic deviation correction, automatic fault detection prompts, convenient maintenance. The operation of equipment is personalized without manual involvement. The automatic fault alarm prompts the operator to locate the fault and its phenomenon, as well as the method of fault detection and treatment.

3. Fully automatic packaging machine can be used in any production line that needs to use packaging bags to realize the automation of material packaging process.

4. Fully automatic packaging machine can automatically control the working process of the production line of the automatic packaging machine through intelligent program control. It can realize continuous operation, with the functions of fault alarm, display and automatic interlocking shutdown. It can also equip communication interface according to the needs of users to realize real-time monitoring, remote diagnosis and network management of the automatic packaging scale.

四、Main technical parameters of fully automatic packaging machine:

1. Weighing range: 20-50 kg/bag

2. Weighing accuracy: ≤0.2%

3. Packaging capacity: 800-1200 packages of hours

4. Power supply: 380VAC/220VAC 50HZ

5. Control power supply: 24VDC

6. Controlled gas source: 0.5-0.8 MPa

【Related Product】

- Bulk Full-automatic Loading Machine

- Pallet Full-automatic Loading Machine

- Ton Bag Full-automatic Loading Machine

- Small Bag Full-automatic Loading Machine

- Fully Automatic Bulk Bag Packaging Machine

- SW-JP-F-25 pumping type vibration feeding packaging machine

- Full - automatic packaging machine for organic fertilizer

- Valve Packing Machine/Scale

【Relevant Articles】

- Application Characteristics of Potassium Dihydrogen Phosphate Full-auto

- How to Select the Type of Full-automatic Ton Bag Packing Machine for Co

- Selection of Automatic Packing Machine for White Granulated Sugar Produ

- Detection and anticorrosion of electrical components of automatic packi

- Requirements of Full-automatic Ton-bag Packing Machine for Ton Bags

- The selection and application of potassium tert-butyl alcohol in automa

- Zaozhuang Sunweigh teaching you how to choose packaging machine

- Leadership of the municipal government to visit Zaozhuang Sunweigh Tech

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018