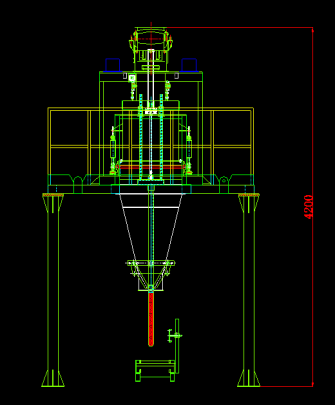

Liquid filling machine

Introduction to LCS Products of Liquid Filling Machine

LCS series of liquid Filling Machine can meet the needs of automatic filling of various liquids. The system is equipped with a filling device on or below the liquid level. The unique spray gun device is easy to operate. The filling is fast and accurate, and the residual liquid leakage is avoided to the greatest extent when the filling is completed. Suitable for safe environment, can fill a variety of specifications of containers. In operation, the operator only needs to simply move the container so that the filling port of the container is directly below the nozzle of the spray gun, press the "start" button, the spray gun drops automatically, the empty barrel peels automatically, and then fills accurately and quickly. At the end of filling, the spray gun is automatically lifted out of the barrel. The operator removes the full barrel and ends a filling cycle.

LCS Functional Characteristics of Liquid Filling Machine

The liquid Filling Machine can set single-speed and double-speed filling, and the quantity is accurate and reliable. Automatic drop compensation, anti-drip and leakage design, reduce waste. With barrel detection function, single barrel, multi-barrel filling. Working mode: Semi-automatic: manual upper and lower containers, manual counterparts, automatic filling; Working mode: automatic: automatic upper and lower containers, automatic searching, automatic positioning, automatic filling.

LCS Options for Liquid Filling Machine

The liquid Filling Machine is used for explosion-proof configuration in dangerous areas, pipelines and ball valves coated with Teflon, high-precision weighing device, food-grade configuration, gas extraction device, barrel pressure device, conveying roller, bucket stabilization device, anticorrosion configuration and recommended configuration.

LCS Technical Parameters of Liquid Filling Machine

| Specifications | LCS-30-GC | LCS-300-GC | LCS-500-GC | LCS-1000-GC |

| Weighing range (kg) | 12-30 | 120-300 | 200-500 | 400-1000 |

| Grading value (g) | 10 | 100 | 200 | 500 |

| Gas Source Pressure (Mpa) | 0.6-1 | 0.6-1 | 0.6-1 | 0.6-1 |

| Filling Pressure (Mpa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 |

| Filling speed (barrel/hour) | 120-150 | 40-60 | 30-40 | 10-20 |

| Accuracy grade | QIML R61*(0.2)↓ | |||

-

You may be interested in: liquid quantitative filling machine

-

Recommended Solutions: Powder Material Quantitative Packaging Machine Solutions Mixed Material Packaging Machine Solutions Particle Packing Scale Solutions

【Related Product】

- Bulk Full-automatic Loading Machine

- Pallet Full-automatic Loading Machine

- Ton Bag Full-automatic Loading Machine

- Small Bag Full-automatic Loading Machine

- Fully Automatic Bulk Bag Packaging Machine

- SW-JP-F-25 pumping type vibration feeding packaging machine

- Full - automatic packaging machine for organic fertilizer

- Valve Packing Machine/Scale

【Relevant Articles】

- Application Characteristics of Potassium Dihydrogen Phosphate Full-auto

- How to Select the Type of Full-automatic Ton Bag Packing Machine for Co

- Selection of Automatic Packing Machine for White Granulated Sugar Produ

- Detection and anticorrosion of electrical components of automatic packi

- Requirements of Full-automatic Ton-bag Packing Machine for Ton Bags

- The selection and application of potassium tert-butyl alcohol in automa

- Zaozhuang Sunweigh teaching you how to choose packaging machine

- Leadership of the municipal government to visit Zaozhuang Sunweigh Tech

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018