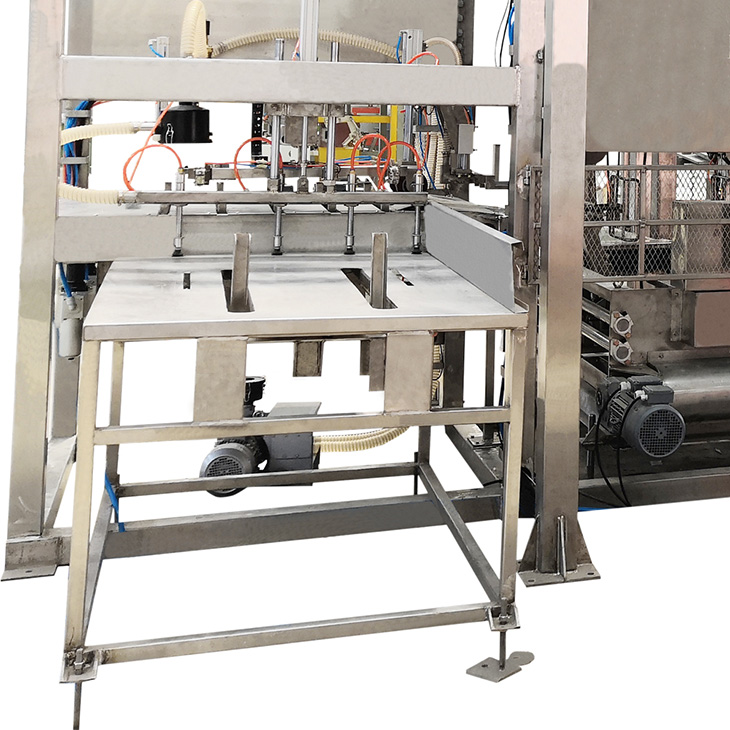

Fully automatic bagging machine

Zaozhuang Sunweigh Technology Co., Ltd. has rich experience in the industry of automatic bagging machine. The products are patented by the state, made of stainless steel, all electrical components are imported components, with high configuration, and never drop bags to prevent waste caused by bagging machinery. Automatic bagging machine, also known as "automatic bagging machine", "automatic bagging machine", "automatic bagging machine", "bagging manipulator". Bagging manipulator completely simulates manual bagging, with clear action and no redundant action. It is a replacement product that replaces manual bagging and reduces the work intensity of personnel.

The automatic bagging machine is divided into SW-ABF-CK which is suitable for valve pockets and SW-ABF-CF which is used for open pockets. The mechanical structure and installation size are totally different. The nature of bags determines the difference of the two bagging methods. Material shapes and properties are different, and automatic bagging machines are also different.

The working process of SW-ABF fully automatic bagging machine:

1. Separation of packing bags: A stack of packing bags need to be manually put into the bag warehouse. The sucker sucks an empty packing bag from the top of the stack of packing bags. The lifting cylinder pulls the packing bag up. The side clamping device drags the packing bag to the other side and reaches the finishing position.

2. Packing Bag Finishing: Packing bags are folded by the finishing device to ensure the neatness of the packing bags.

3. Transportation of packing bags: Roll the pouring rollers and transport the packaged bags to the opening place.

4. Opening and grabbing of packing bags: empty packing bags reach the opening position, the upper and lower suckers press the packing bags at the same time, pull the opening of the packing bags in two directions upward and downward, grab the bag hand deep into the packing bags, grab the upper and lower sides of the packing bags at the same time, and complete the opening and grabbing of the packing bags.

5. Packaging bag bagging: After the bag is grasped by the bag handler, the bag mouth is enlarged, the size is larger than the lower opening of the packing scale, the rocker arm is turned upward, and the bag is put into the lower opening to complete the bagging process; after the bag is put into the lower opening, the cylinder is clamped before and after the bag is put into the lower opening, under the control of the output signal of the controller, and the clamping signal is transmitted to the master control instrument, and the instrument is connected. After receiving the signal, the material is put into the packaging bag to complete the automatic bagging process.

Functional features of SW-ABF fully automatic bagging machine:

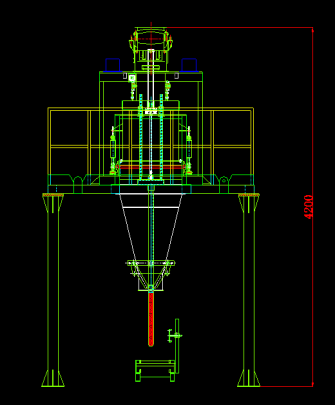

Technical parameters of SW-ABF automatic bagging machine:

Product Model: SW-ABF-CK

Packing materials: particulate matter

Packing range: 20-50 kg

Packing bag type: open pocket

Packing speed: 800 - 1200 packs per hour

Packing materials: paper bags, woven bags (at least one coating)

Product model: SW-ABF-CF

Packing materials: powder materials

Packing range: 20-50 kg

Packing bag type: valve pocket

Packing speed: 400 - 600 packs per hour

Selection Guide for SW-ABF Fully Automatic Bagging Machine:

SW-ABF-CK fully automatic bagging machine is suitable for open-pocket packaging machines such as flour packaging bags and flour packaging machines; SW-ABF-CF fully automatic bagging machine is suitable for valve pocket packaging machines, such as cement packaging bags, filling bags also choose sealer scale and valve mouth bagging machine.

1. First of all, confirm the shape of the bag mouth: valve pocket or open pocket;

2. Dimensions of packaging bags and pockets;

3. Strictly speaking, we should use all kinds of packaging bags, including paper bags, plastic bags and composite bags, to meet the needs of various packaging scales. We must ensure that one side is covered with film and the weight is over 100 g.

4. Physical characteristics of filling materials: shape, performance, moisture content, fluidity, temperature, etc.

5. Installation size, whether there is enough installation location;

6. Weighing and packaging unit is net or gross weighing.

7. The conveying mode and folding sealing mode of packing bags after filling materials;

8. The automatic weighing unit and the conveying and sealing unit must be linked, otherwise the unmanned and accurate work can not be realized.

9. Whether the environment needs anti-corrosion, explosion-proof and dust-proof, it can be customized according to the needs of customers.

10. The output of the whole production line, the maximum product per hour is how many tons, how many bags need to be packed, to see whether the automatic bagging machine can meet the demand;

11. Our company now carries out the transformation of semi-automatic packaging scale, and installs automatic bagging machine, which greatly improves the production efficiency instead of manual bagging.

SW-ABF Fully automatic bagging machine after-sales service and use considerations:

1. After the equipment is sold, we will send professional technicians to install and debug the equipment so as to ensure the normal, stable and orderly operation of the equipment. At the same time, we will train the user's operators in the operation and maintenance of the equipment, so as to ensure that the operators are skilled in the operation and maintenance of the equipment.

2. Actively provide technical guidance for the problems encountered by customers in the use process. When the users can not solve the problems, send technical personnel to the customer site to solve them, and make regular visits to customers;

3. If the equipment accessories are damaged, the company will replace them free of charge during the repairing period. If the equipment is beyond the warranty period, we will replace them at the most favorable price to ensure that the users have no worries.

4. Provide users with complete equipment electrical information and operation instructions;

5. Detailed matters needing attention in the use of equipment should be referred to the instructions.

【Related Product】

- Bulk Full-automatic Loading Machine

- Pallet Full-automatic Loading Machine

- Ton Bag Full-automatic Loading Machine

- Small Bag Full-automatic Loading Machine

- Fully Automatic Bulk Bag Packaging Machine

- SW-JP-F-25 pumping type vibration feeding packaging machine

- Full - automatic packaging machine for organic fertilizer

- Valve Packing Machine/Scale

【Relevant Articles】

- Application Characteristics of Potassium Dihydrogen Phosphate Full-auto

- How to Select the Type of Full-automatic Ton Bag Packing Machine for Co

- Selection of Automatic Packing Machine for White Granulated Sugar Produ

- Detection and anticorrosion of electrical components of automatic packi

- Requirements of Full-automatic Ton-bag Packing Machine for Ton Bags

- The selection and application of potassium tert-butyl alcohol in automa

- Zaozhuang Sunweigh teaching you how to choose packaging machine

- Leadership of the municipal government to visit Zaozhuang Sunweigh Tech

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018