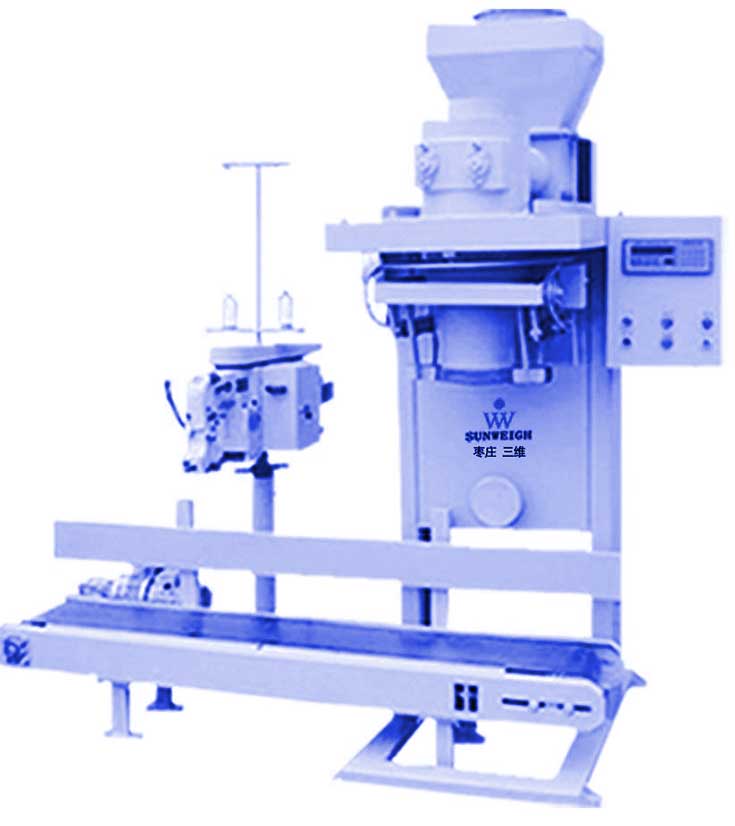

Bran Quantitative Packaging Machine

Zaozhuang Sunweigh Technician Co., Ltd. produces a professional bran quantitative packaging machine DCS-50F, which automatically weighs, packs, sews and outputs bran. The bran quantitative packaging machine DCS-50F is a new type of high-performance packaging machine independently developed by our company and with independent intellectual property rights. It is suitable for automatic quantitative powder packaging equipment in flour, starch, feed, food, chemical, light industry, medicine and other industries. The bran quantitative packaging machine DCS-50F is mainly equipped with weighing mechanism, feeding mechanism, body frame, control system, conveyor and sewing machine. It needs manual bagging.

The working principle of the bran quantitative packaging machine DCS-50F is as follows: before packaging, the target weight should be set artificially on the instrument. Customers can adjust themselves according to their needs. The packaging bag is put into the lower outlet manually, the clamp switch is moved, the control system receives the signal of the bagging, and then the cylinder is driven. The bag is clamped by the clamp. At the same time, the feeding mechanism is started to feed the bran in the bin into the packaging machine. The feeding mechanism is as follows: Double helix feeding, when reaching the target weight, the helix stops feeding, the belt opener opens automatically, and the packing bag falls on the conveyor automatically. The conveyor conveys the packing bag back to the manual auxiliary seam opening, and then conveys it backward to complete a bag filling process.

Functional characteristics of bran quantitative packaging machine DCS-50F

The bran quantitative packaging machine is easy to operate: the weight is adjusted by instrument, and the operation is simple and fast.

The bran quantitative packaging machine has high precision: high precision weighing controller is selected, and the reliability is good.

The bran quantitative packaging machine has good integrality: small area, flexible and convenient installation;

The speed of bran quantitative packaging machine can be adjusted: screw feeding, fast feeding and slow feeding can be realized by the controller, and the feeding speed can be set arbitrarily;

Environmental protection operation of bran quantitative packaging machine: Close internal circulation system, effectively prevent dust from flying, improve working environment and protect employees'health;

The structure of bran quantitative packaging machine is reasonable: compact enough, compact enough, and can be made into fixed or mobile body according to user's requirements;

Selected parts of bran quantitative packaging machine: folding machine, automatic sealing machine and dust removal unit can be selected at random.

Technical parameters of bran quantitative packaging machine DCS-50F

Model Specification: DCS-50F

Weighing range: 10-50 kg

Grading value: 10g

Weighing accuracy: 0.2% F, S

Weighing speed: 200-300 bag/h

Working environment: relative humidity ≤ 90%

Power supply: AC380V50Hz

Air pressure: 0.4-0.8 Mpa

Power: 3.0kw

Air consumption:1m³/h

Zaozhuang Sunweigh Technology Co., Ltd.'s original solution of changing semi-automatic packaging machine into automatic packaging machine. For semi-automatic packaging machine, manual bagging is changed into mechanical bagging, SW-ABF automatic bagging machine or SW-ABF automatic bagging machine is added. The folding sealing machine is changed into automatic folding sealing without manual assistance, and automatic detection sensor is added to realize the self-operation of the equipment. Dynamic control; the whole packaging, folding sealing and conveying are controlled by PLC without manual participation.

Zaozhuang Sunweigh Technology Co., Ltd. originally applied the automatic folding sealing machine to the semi-automatic packaging machine. Only one person needed to carry out manual bagging. After filling materials, there was an automatic folding sealing machine for packaging bags, which realized the automatic folding sealing, saved labor and improved the production efficiency of enterprises. Users can reconstruct two solutions according to their needs to reduce labor input and improve production efficiency.

【Related Product】

- Full-automatic Packaging Machine

- Semi-automatic valve bag packing machine

- Semi automatic powder packaging machine

- SW-ATF-180 Fully Automatic Packaging Machine for Ton Bag

- Semi-automatic Ton bag Packing machine

- Double hopper granule packing machine

- Single hopper packing machine

- Semi-automatic packing machine without hopper

【Relevant Articles】

- Application Characteristics of Potassium Dihydrogen Phosphate Full-auto

- How to Select the Type of Full-automatic Ton Bag Packing Machine for Co

- Selection of Automatic Packing Machine for White Granulated Sugar Produ

- Detection and anticorrosion of electrical components of automatic packi

- Requirements of Full-automatic Ton-bag Packing Machine for Ton Bags

- The selection and application of potassium tert-butyl alcohol in automa

- Zaozhuang Sunweigh teaching you how to choose packaging machine

- Leadership of the municipal government to visit Zaozhuang Sunweigh Tech

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018