A fully automatic palletizer that does not scratch bags and can be installed anywhere

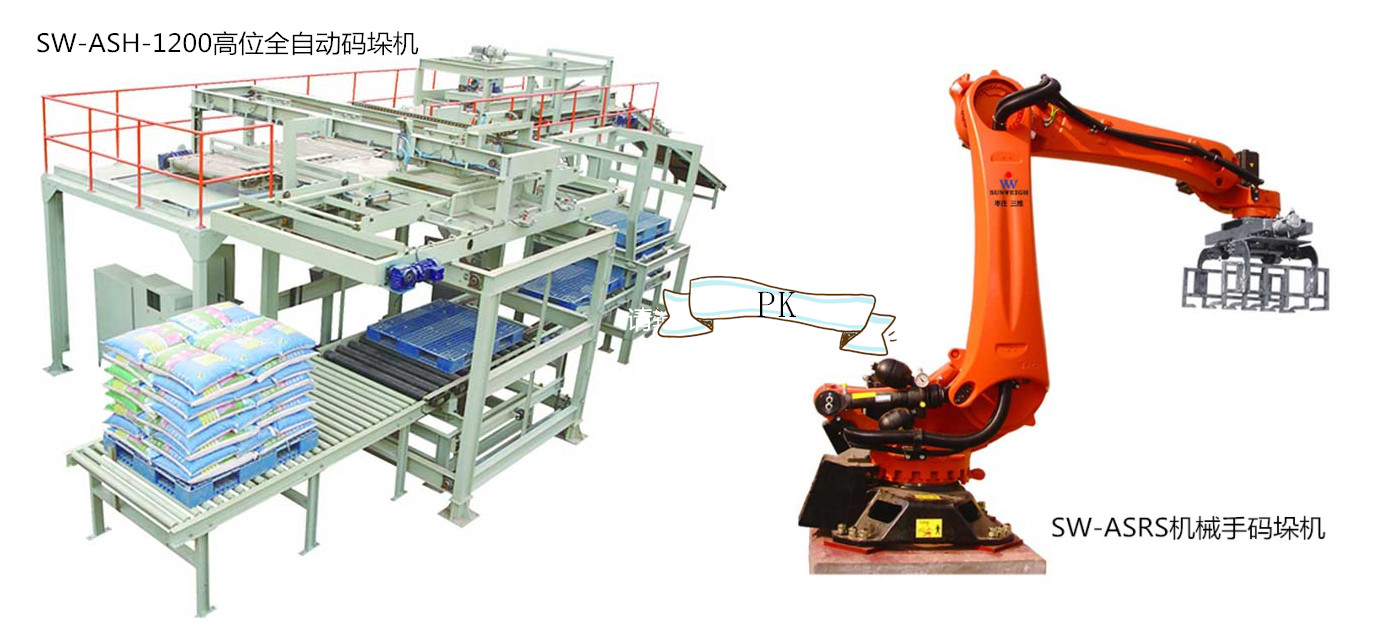

Manipulator palletizer is well known as a hand-like device. The SW-ASRS of Zaozhuang Sunweigh manipulator palletizer is mainly composed of leveling, buffering conveyor, grabbing roller, tray machine, manipulator and other devices. The whole palletizing process starts with the conveyor conveying qualified bags to the leveller to press the bags to make the bags flat. After the bags reach the grabbing roller, the bags detected by the manipulator are grabbed, steered, stacked and stacked in layers, thus completing the whole palletizing process. But it has a disadvantage like a manual manipulator device. If the bag is not neat enough, it will scratch the bag when grabbing it. Because the structure of the manipulator is simple and easy to install, it can also stack the finished products of different specifications at the same time. It also meets the stacking requirements of three conveyor lines, so it has been favored by many customers since it came into the market. Zaozhuang Sunweigh not only has the compact structure of manipulator to install simple palletizer, but also has a fully automatic palletizer SW-ASH-1200, which will not scratch bags. As the name implies, the installation height of high-position palletizer is much higher than that of manipulator palletizer, and the high-position automatic palletizer can only stack a kind of finished product with one specification and one conveyor line. Palletizing demand, and the cost of early input is nearly 10 times higher than that of the manipulator, so customers generally pay little attention to it. However, the stacking speed of high-position palletizer can reach 1600 packages per hour, the stacking shape is neat, beautiful and firm, which is more efficient than the traditional manual palletizing. This is beyond the reach of the manipulator, and all the bags with the mouth facing inward can realize automatic grouping and layering. Manipulators can generally stack 800 bales/hour, and their hands can reach 1000 bales/hour palletizing speed; general manipulator palletizers can be used for 6-8 years, while high-level automatic palletizers can be used for 100 years, and their service life is more than 12 times longer; high-level palletizers can be used in any area, while manipulator palletizers can not be used in Plateau areas, mostly in Northern areas; There will be 1-3W maintenance fee per year, which is not available for high-level palletizers and saves a lot of money in the long run.

Technical parameters of SW-ASH-1200 automatic high-position palletizer:

Product model: SW-ASH-1200

Palletizing capacity: 1200 bag/h

Palletizing Layer Number: 1-8 Layers

Power supply: AC380V 50Hz

Air pressure: 0.5-0.8 Mpa

Power: 16kw

Air consumption: 1.5m³/min

Scope of application: boxes, film bags, packaging bags (polypropylene, polyethylene woven bags, kraft paper bags)

- Last:Polyethylene Fully Automatic High Position Palletizer

- Next:SW-ABF Fully Automatic Packaging Machine Instructions Part I

【Related Product】

- Full-automatic Packaging Machin

- Semi-automatic valve bag packin

- Semi automatic powder packaging

- SW-ATF-180 Fully Automatic Pack

- Semi-automatic Ton bag Packing

- Double hopper granule packing m

- Single hopper packing machine

- Semi-automatic packing machine

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018