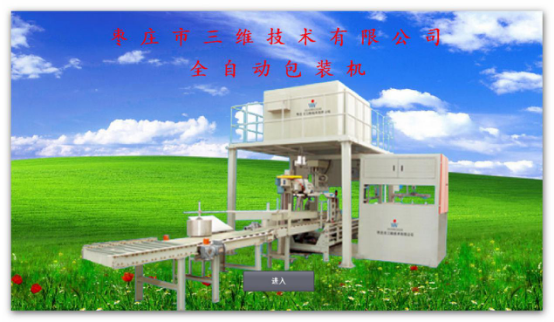

SW-ABF Fully Automatic Packaging Machine Instructions Part I

一、 Instructions for Equipment

1. Overview

SW-ABF-800 automatic packaging machine is a high-quality and high-performance automatic packaging machine developed and produced by our company independently. It has a series of functions, such as automatic weighing and measuring, automatic bagging, automatic bagging, automatic folding seam package and finished product conveying. This machine adopts high precision and high reliability mechanical system, PLC program control, advanced touch human-machine interface, making the operation of the whole machine more simple and perfect. The equipment can be widely used in packaging granules, powders and mixtures in various industries, so that customers can improve production efficiency, reduce labor intensity and reduce labor costs of the preferred equipment.

2. Performance and specifications

| Power Supply | 380V/50HZ | Total power | 2.5KW |

| Packaging | Paper bag, woven bag (film) | Measurement range | 150-1000ML |

| Packaging speed | 200-1200Pack/hour | Use air pressure | 0.8-0.8MPa |

| Packaging materials | Particles, powders, flakes, mixtures | Air consumption | 1.6 cubic/min |

| Weight | Outline size |

二. Configuration and Work Flow of the Whole Machine

1. Composition of the unit:

A. The weighing system consisting of a hopper, a feeding device, a blanking hopper and a high-precision weighing device.

B. Fully automatic bagging, bagging, bagging, automatic folding, sewing and packing product delivery and palletizing system.

2. Functional process

Packaging materials flow into the eight-shaped hopper from the user's silo and enter the feeding device separately. When the electronic control system receives the instructions from the beginning of weighing, the two actuators of the feeding device, the coarse feed cylinder and the fine feed cylinder, act simultaneously, that is, the two feed arc doors open simultaneously, the material flow into the barrel (when the bottom door of the barrel should be closed) starts to measure, and when the weight in the barrel begins to measure. When the rough feed cylinder is reset and the feeding arc door (I) is closed, the material can still flow into the barrel from the small hole of the arc door. When the inflow reaches the pre-set fine value, the fine feed cylinder is reset, the feeding arc door (II) is closed, and the electric control system shows the actual weighing, and the one-time weighing cycle ends. The automatic bag-feeding machine sets the bag, after the action of the bag-clamping cylinder, the bag is clamped. At the same time, the bottom door of the barrel opens. The measured material enters the bag through the hopper. According to the preset time, the bottom door of the barrel closes. If the closing position is correct, the next weighing process automatically proceeds. If the closing position is not in place, the weighing process stops.

三、 Installation Notes

1. The base surface should be horizontal and its flatness should not exceed 2 mm. The foundation must be away from the source of vibration.

2. After installation, appropriate clearance should be left between the bolt on the safety bracket and the barrel bracket so as not to affect weighing and play a protective role.

3. Sensors must not be subjected to any additional current or mechanical overload.

4. The electric control system must be grounded a. The protective grounding is less than 4 ohms. B. Signal grounding is less than 1 ohm.

四、 Operation

Pre-boot check

1. It is necessary to exclude the factors that do not affect the work of the machine.

2. Turn on the power switch and check whether it meets the rated value.

3. Check whether the compressed air pressure is in the range of 0.55 Mpa.

4. Are empty bags neatly placed?

5. Whether the bagging platform is foreign body or not.

Boot up

Closed control system, motor drive and other control cabinet power supply, touch screen and instrument power on, touch screen into the welcome screen:

- Last:A fully automatic palletizer that does not scratch bags and can be installed anywhere

- Next:SW-ABF Fully Automatic Packaging Machine Instructions Part II

【Related Product】

- Full-automatic Packaging Machin

- Semi-automatic valve bag packin

- Semi automatic powder packaging

- SW-ATF-180 Fully Automatic Pack

- Semi-automatic Ton bag Packing

- Double hopper granule packing m

- Single hopper packing machine

- Semi-automatic packing machine

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018