SW-ABF Fully Automatic Packaging Machine Instructions Part II

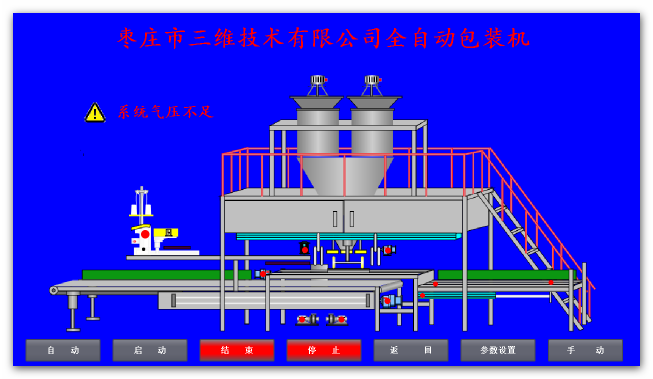

Click "Enter" to enter the running screen, as shown in the figure.

Operating screen display device schematic diagram, operation button, operation indicator and related alarm information.

Before starting, the parameters should be set and confirmed (usually obtained by debugging or production experience).

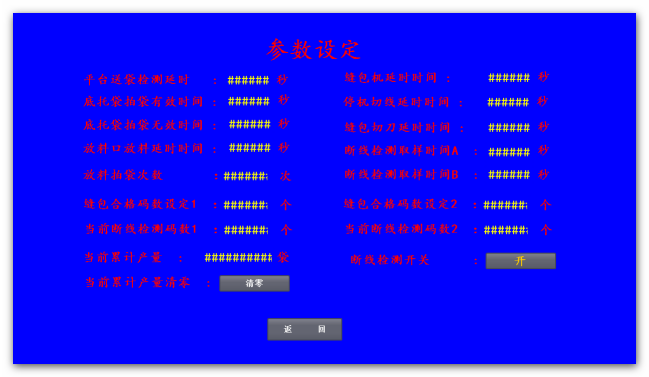

Click the "Parameter Settings" button on the screen to enter the settings screen, as shown in the figure.

The significance of the parameters is as follows:

1. Platform bag delivery delay - refers to the confirmation time of the arrival of a whole pile of empty bags in the absence of bags. The significance of this parameter is to prevent the false suction action caused by the detection of bags and the absence of bags.

2. The effective time and invalid time of bottom towing bag determine the frequency of bottom tapping. The bottom tapping is helpful for the solid material in the bag.

3. Delay time of discharging at discharging inlet is the delay time of discharging process.

4. The number of times to pat bags is set according to the need, and the patting bags are only effective in the process of discharging materials.

5. Setting 1 and 2 of qualified code number of sewing packages is the minimum number of codes recorded by a pack of coders in the state of continuous sewing while the detection mode of broken lines is the code number judgement. When the measured code number is lower than this value, it is judged as broken lines.

6. The current number of broken line detection codes 1 and 2 are the codes recorded by a pack of coders under the continuous line condition which is actually detected. This parameter can not be set. It only provides a reference for setting up the qualified number of seam packages.

7. The current cumulative output record shows the current cumulative production volume, which can be re-recorded periodically through the clearing button.

8. The delay time of sewing machine is the effective delay time of wire break detection.

9. Delay tangential time of sewing machine; Delay tangential time of sewing package; This parameter determines the length of towing line.

10. The delay time of sewing and wrapping cutter is the time for the cutter to perform an action, which is usually set to 0.3 seconds.

11. Sampling time A and B of disconnection detection are the interval time between the two pulses of the encoder when the disconnection detection mode is the interval time judgment mode. Because of the different rotating speed of the two encoders, the two parameters are also different.

12. The disconnection detection switch is only used in the process of equipment debugging.

After the parameters are set or checked correctly, it can return to the running screen for the next operation.

Manual picture

The device can execute the action of a single executive component in the manual state. This function can be used in the debugging process or in the production process when unexpected circumstances occur.

Automatic operation of equipment

Return to the running screen

- Last:SW-ABF Fully Automatic Packaging Machine Instructions Part I

- Next:SW-ABF Fully Automatic Packaging Machine Instructions Part III

【Related Product】

- Full-automatic Packaging Machin

- Semi-automatic valve bag packin

- Semi automatic powder packaging

- SW-ATF-180 Fully Automatic Pack

- Semi-automatic Ton bag Packing

- Double hopper granule packing m

- Single hopper packing machine

- Semi-automatic packing machine

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018