Henan Compound Fertilizer Fully Automatic Packaging and High-level Palletizing Production

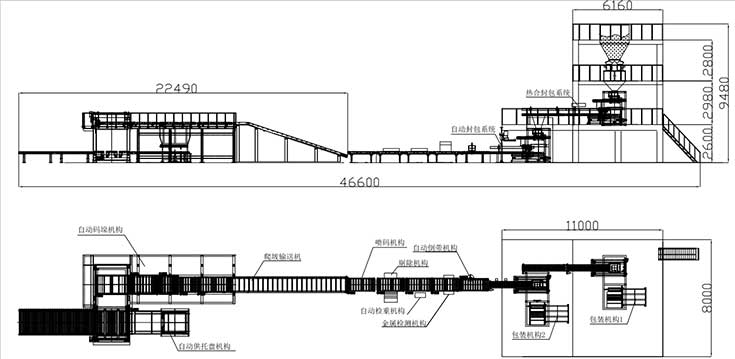

Equipment Composition of Compound Fertilizer Fully Automatic Packing and High-level Palletizing Production Line

Zaozhuang Sunweigh Technology Co., Ltd. produces full-automatic high-level palletizing production line for compound fertilizer packaging, which mainly consists of full-automatic packaging scale and high-level automatic palletizing machine.

一、Fully Automatic Packaging Scale

The automatic packaging scale is mainly composed of: quantitative packaging scale, automatic bagging machine, bag clamping device, automatic folding machine, automatic sewing and packaging device, finished product conveyor, dust removal system (optional) and so on.

1. Brief Introduction of Fully Automatic Bagging Machine Equipment

The automatic bagging machine in the automatic packaging scale is to complete the automatic grasping, automatic finishing, automatic opening and automatic bagging of bags. It realizes the automatic operation from bulk material to woven bag packaging, saves the input of manpower, material and financial resources, reduces the production cost for customers and improves the production efficiency of automatic packaging scale. The automatic bag feeding machine can widely use the packaging of various industries and materials. It is the necessary equipment for enterprise automation process.

2. Automatic Bag-holding Device with Packing Scale

When the packing bag after filling material is laid down at the lower opening, the bag is held in the middle of the bag by the special processing bag-holding cart and the bag mouth is clamped and sent to the movable guiding device, which is connected with the sewing and packaging system. After entering the sealing transmission chain, the bag mouth is guaranteed to be in a zigzag shape, so that the bag can be controlled in the whole process.

3. Brief Introduction of Automatic Sewing and Packaging of Fully Automatic Packaging Scale

The automatic sewing and packaging device of automatic packaging scale is composed of automatic folding machine, sewing machine, wire breaking alarm, electrical control system, etc. The bags filled with materials are imported into the conveyor by the automatic import system, sewed automatically, cut automatically, and then output automatically. If thread breakage occurs, the sewing machine control system will automatically alarm and send interlocking stop signal, and there are on-site position detection and operation buttons.

4. Brief Introduction of Fully Automatic Packaging Scale Product Conveyor

The product conveyor of automatic packaging scale is to smoothly transport sealed bags through various devices at a constant speed. The speed can be adjusted by frequency converter, which matches the speed of sewing machine. Conveying length: According to the actual situation of the site, it can also be customized according to customer needs.

5. Introduction of Dust Removal System of Fully Automatic Packaging Scale

Zaozhuang Sunweigh Technology Co., Ltd. fully automatic packaging scale dust removal system, a number of suction points on the material warehouse, packaging scale, lower inlet and outlet for dust removal, so that no dust on the packaging site, to meet environmental requirements.

二.High automatic palletizer

High automatic palletizer is mainly composed of climbing conveyor, transition buffer, bag press, rotating bag posture adjusting device, weaving and assembling device, bag conveyor, pallet automatic feeder, finished pallet conveyor, etc.

1. High-level automatic palletizer controls the operation panel through touch screen, adopts PLC control, realizes human-computer interaction through friendly interface of touch screen, and realizes the monitoring of the production process on site.

2. Packing bag flattening device, the use of reasonable mechanical structure to achieve the flattening operation of packaging bags, so that materials are evenly filled with packaging bags, keep the shape of the bag flat.

3. The position adjustment device for stacking and turning bags can rotate the packing bags (+90 or 180 to make the inside of the sewing mouth of all the bags more beautiful and firm.

4. Arrangement device, high sensitivity detection switch controls the start and stop of marshalling conveyor and bag picking manipulator, and realizes the orderly arrangement of packaging bags.

5. The stacking layered lifting device realizes the stacking of the largest eight-layer packaging bags by position control. The empty pallet is automatically supplied, and the movement is continuous, accurate and reliable.

6. Typical palletizing diagram, the palletizing of 5 packages of *8-10 layers realized on pallets, is output by the bag conveyor, and the palletizing is neat and beautiful.

Main features of high-position automatic palletizer:

1. High-position automatic palletizer has a wide range of applications and is suitable for the stacking requirements of various packaging bags.

2. High automatic palletizer has a high degree of automation (full automatic flattening, full automatic bagging, full automatic hierarchical grouping);

3. All the bags are facing inward with beautiful and firm stacking shape.

4. High-position automatic palletizer is more efficient than traditional manual palletizer and saves manual investment.

5. High automatic palletizer can be used for pallets of various materials and sizes.

6. High-position automatic palletizer has reasonable structure and high stability.

Technical parameters of high-position palletizing production line for full-automatic packaging of compound fertilizer

| Packaging scope | 20-50kg |

| Packaging capability | 200-1200bag/h(Adjustable speed) |

| Packing Bag Form | Film-coated woven bags |

| Sealing type | Automatic sewing machine sewing bag (to ensure that material does not leak from the needle hole) |

| Verification mode | Automatic reexamination |

| Surface Material Contacted with Material | 304 stainless steel (all stainless steel structure can be selected according to workshop environment and materials) |

| Gas source | 0.4-0.8Mpa |

| Air consumption | 96㎥/h |

| power | 15KW |

| Packaging accuracy | ±2‰FS |

| Pallet weight | 20-50kg |

| Palletizing capacity | 200-1200bag/h(Adjustable speed) |

| Palletizing number | 1-10层 |

| Palletizing height | 2500mm |

| Palletizing weight | 1000kg-2500kg |

| Power Supply | 380V、50HZ |

| Gas source | 0.5-0.8Mpa |

| Air consumption | ~90㎥/h |

| power | ~24KW |

| Tray size | 1400mm(long)*1200mm(wide)*150-160mm(tall) |

After-sales Service of Compound Fertilizer Fully Automatic Packaging High-level Palletizing Production Line

1. Construction: The company is responsible for field installation and commissioning;

2. Acceptance and acceptance: After installation and commissioning are completed, the customer accepts the acceptance, and the supplier's personnel can leave the scene only after they are qualified.

3. Fully automatic packing and high-level palletizing production line is guaranteed for one year. Our company provides free maintenance for equipment damage caused by supplier's quality reasons, and lifelong maintenance for equipment of your unit. If the equipment is not damaged due to the quality reasons of the supplier, our company is responsible for maintenance, and only charges a cost fee.

4. If there is an emergency failure or shutdown of equipment or control system during the warranty period, provide the list and contact information of maintenance personnel within 2 hours after receiving the request for help information from the demander, and let the technician call the demander's technical personnel within 2 hours, judge the equipment failure through the demander's technical personnel's oral description and give solutions; if the telephone guidance is not yet available; To solve the problem, the supplier will immediately send technicians to the scene to solve the problem, and the cost will be borne by the supplier. The buyer shall be fully responsible for the defects or losses of parts or structures caused by improper design, manufacture, installation and commissioning of all goods within the scope of the contract, the failure to meet the expected performance indicators and the occurrence of accidents.

5. After the end of the warranty period, the supplier still provides lifelong maintenance services, but the costs incurred are borne by the buyer. After the end of the quality guarantee period, the buyer will be responsible for handling simple accidents and emergency maintenance, and daily maintenance and maintenance according to the requirements of the operation manual.

- Last:Fujian Refractories Unshaped Ingredients and Mixed Packaging Production Line

- Next:Rizhao polypropylene factory purchased three-dimensional technology packaging machine in 20

【Related Product】

- Full-automatic Packaging Machin

- Semi-automatic valve bag packin

- Semi automatic powder packaging

- SW-ATF-180 Fully Automatic Pack

- Semi-automatic Ton bag Packing

- Double hopper granule packing m

- Single hopper packing machine

- Semi-automatic packing machine

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018