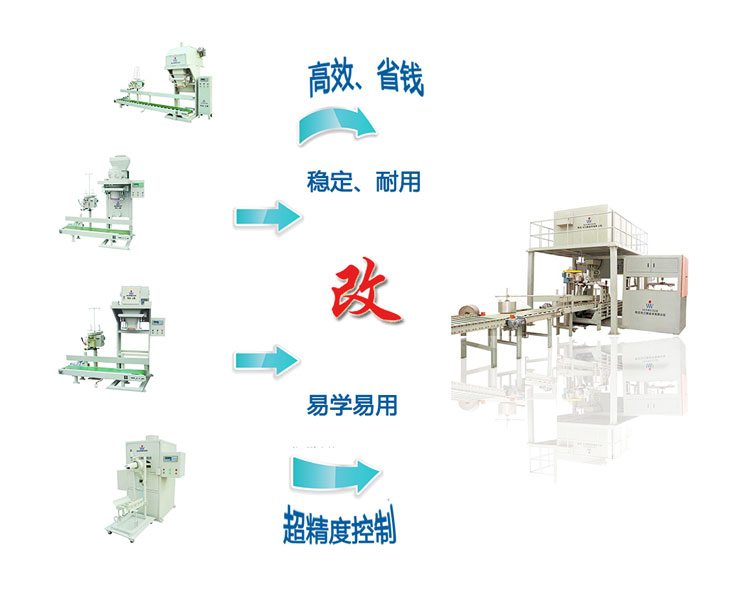

Reform of Semi-automatic Packing Scale to Fully Automatic Packing Scale

Generally speaking, semi-automatic packaging scale refers to the packaging scale by manual bagging (bagging). Fully automatic packaging scale refers to the packaging scale by manual bagging, automatic folding, automatic sealing, automatic output without manual participation.

It is a plan to replace the semi-automatic packaging scale with an automatic packaging scale; a better plan is to change the original semi-automatic packaging scale into an automatic packaging scale. In short, the semi-automatic packaging scale will eventually be replaced by the automatic packaging scale, which is the evolution of equipment and social progress.

The reasons are as follows:

1. The higher the cost of manual use, the more expensive it is to buy the full-automatic packaging scale, but it saves money when it is used, and if it continues to be used, it will make money for you.

2. Improve the management level, as long as the power supply.

3. Fewer and fewer suitable operators make it difficult to recruit.

4. Industrial environment has odor and dust. Environmental protection requirements are getting higher and higher. Machines are needed to replace human beings.

5. The technology of automatic packaging scale and automatic bagging machine is becoming more and more mature, and the purchasing cost is getting lower and lower.

6. Realize high-speed modern continuous production.

The transformation of semi-automatic packaging scale into full-automatic packaging scale mainly consists of three parts:

1. Change manual bagging into manual bagging, add SW-ABF automatic bagging machine or automatic bagging machine SW-ABF.

2. Change the folding sealing machine into full automatic folding sealing machine.

3. Install automatic detection sensors to realize automatic control of equipment operation; the whole packaging, folding sealing and conveying are controlled by PLC without manual participation.

Some people misunderstand that it is a misunderstanding to buy an automatic bagging machine or a fully automatic bagging machine can be installed to achieve full automatic packaging function. If only the bagging function can be realized, the automatic folding and sealing can not be realized or the automatic control operation of the whole system can not be realized, and the purpose of saving labor can not be realized, and the cost can not be saved.

There are two main points in transforming semi-automatic packaging scale into automatic packaging scale.

1. Can Fully Automatic Operation be Achieved

2. Whether the operation of semi-automatic packaging scale is stable after transformation

If the equipment modification is completed, the minor faults are continuous and the operation is not stable, the modification will fail.

A fully automatic packaging scale that can not run steadily will cause equipment damage, bag tearing, material leakage, inappropriate sealing, sealing not fully sewn, resulting in material leakage in the whole packaging bag, seriously affecting production and causing the production of the bagging process to stop.

Different materials need different automatic bagging machines

Different automatic bagging machines should be selected for particulate materials and powder materials: SW-ABF-CK automatic bagging machine is an automatic bagging and packaging system for particulate materials, which is stable, efficient and environmentally friendly; SW-ABF-CF automatic bagging machine is an automatic bagging machine system for powder materials packaging, with good dust handling function. According to different materials, it can be added into the material by vacuum pumping mode. Too much air is pumped out to realize quick packing and sealing.

Different materials adopt different folding sealing machines

1. Food-grade materials, whether powder or granule, need to be sealed separately by inner and outer bags. The inner bag is heated first, and then the outer bag is sealed by needle. If the material is easily damp, it needs to be sealed and then sealed with tape. The whole bag mouth is sewed with tape to isolate the material from the outside air.

2. Chemical products vulnerable to moisture are usually sealed separately by inner and outer bags. Some customers use film-coated bags to seal directly and then sew the whole bag mouth with tape.

3. Ordinary particulate materials are usually sewn directly by folding and sealing, and no other process is needed.

4. The folding sealing machine should have the function of automatic detection and tangent breaking.

5. Automatic folding sealing machine and semi-automatic folding sealing machine of automatic packaging scale are not a concept at all.

Fully automatic packaging scale folding sealing machine has the function of additional testing, which is linked with the packaging system, has the function of fault detection and alarm, while semi-automatic packaging scale only has the function of folding sealing and automatic wire breaking.

The main points for attention in changing semi-automatic packaging scale into full-automatic packaging scale are as follows:

1. Space height. Generally speaking, the height of semi-automatic packaging scale is low, and the height of automatic packaging scale should be higher because of the installation of automatic control system and automatic bagging machine.

2. Packaging bags. Artificial bagging scale generally has no requirement for bags. Automatic bagging scale uses vacuum sucker to open and prop up bags, so it requires that the bags are impermeable, that is to say, they need to be covered with film or double-layer bags, with impermeable inside. The weight of bags should not be less than 100g. Otherwise, it will affect the operation and packing speed of the system.

3. Material characteristics. Whether the material contains moisture, whether it belongs to explosive and flammable, needs special attention in the process of transformation.

4. The performance of electronic components. The highest-end configuration should be adopted to overcome the bad performance of components and parts, which will affect the stable operation of the whole system.

5. Fault tolerance of software. Software is the brain of a system with intelligence and fault tolerance.

6. Speed, accuracy and output. Generally speaking, the speed and precision of automatic packaging system is higher than that of semi-automatic packaging machine. If the speed, precision and products are not as good as semi-automatic, it shows that you are wrong in choosing products.

-

You may be interested in: full automatic packaging scale automatic bagging machine

-

Recommended Solution: Fully Automatic Flanging Sealer Fully Automatic Packing Manipulator Palletizing Production Line Fully Automatic Packing High Position Palletizing Production Line

- Last:Solution of Fully Automatic Flanging Sealer

- Next:The packing line of the packing machine and high-level palletizing machine

【Related Product】

- Full-automatic Packaging Machin

- Semi-automatic valve bag packin

- Semi automatic powder packaging

- SW-ATF-180 Fully Automatic Pack

- Semi-automatic Ton bag Packing

- Double hopper granule packing m

- Single hopper packing machine

- Semi-automatic packing machine

Safety record of Lu Gong net Number 37040202006018

Safety record of Lu Gong net Number 37040202006018